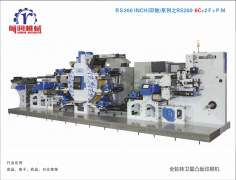

基礎(chǔ)信息

| 前潤S6-370機(jī)組式柔版印刷機(jī) | |

| 機(jī)型Type | 370/450/550 |

| 色組可選Print color | 2-12Colors |

| 最大印刷寬度Max. print width | 370mm/450mm/550mm |

| 印刷長度范圍Print repeat length | 203.2-635mm |

| 最大走紙寬度Max. mechanical speed | 380mm/460nn/560nn |

| 機(jī)械速度Max. mechanical speed | 150m/min |

| 最大放卷直徑Max. unwind dia | ø1000mm |

| 最大收卷直徑Max. rewind dia | ø1000mm |

| 干燥系統(tǒng)Drying system |

可選UV汞燈,、LED UV\熱風(fēng)干燥 Optionai UV mercury lamp,LED UV,Hot air drying |

| 性能Features |

|

1,、無軸傳動(dòng):獨(dú)立雙伺服電機(jī)驅(qū)動(dòng),,支持在線自動(dòng)預(yù)套印和追套印,,調(diào)校簡便,;

Shaftless drive: Independent dual servo motor drive, supports online automatic pre-registration and over-registration, easy adjustment,;

2,、高效印版滾筒:花瓣式結(jié)構(gòu),,換版快捷,,無需大幅調(diào)節(jié),無墨杠,;

Efficient plate cylinder: petal-shaped structure, fast plate change, no need for large adjustments, no ink bar,;

3、大尺寸承印輥配有水冷裝置,,對(duì)無支撐薄膜材料有較好的適應(yīng)性,,適用于印刷多種薄膜材料,如PET,、OPP,、CPP、PP等,;

The large size anvil roller equipped with water chiller, which has good adaptability to unsupported film materials and is suitable for printing a variety of film materials, such as PET, OPP, CPP, PP, etc,;

4、智能不停機(jī)系統(tǒng):可選配不停機(jī)收放卷系統(tǒng),,支持手動(dòng)/自動(dòng)接紙,,提高生產(chǎn)效率;全視覺自動(dòng)套印系統(tǒng),,實(shí)現(xiàn)自動(dòng)套印和數(shù)據(jù)保存,,返單時(shí)可一鍵調(diào)取,自動(dòng)套準(zhǔn),。

Intelligent non-stop system: optional this system, support manual/automatic paper connection, improve production efficiency; full visual automatic overprinting system, realize automatic overprinting and data storage, and can be retrieved with one button when returning the order, and automatically register.

5,、多功能印刷:柔版印刷為主,支持冷燙、覆膜,、除膠,、多層標(biāo)簽、折頁標(biāo)簽,、在線品檢,、模切等工藝,可選配絲印,、噴碼,、凹版等聯(lián)機(jī)功能。

Multifunctional printing: mainly flexographic printing, supporting cold stamping, lamination, Glue removal, multi-layer labels, folding labels, online inspection, die-cutting and other processes, and optional online screen printing, inkjet printing, gravure, etc.

6,、便捷收放料:獨(dú)立料卷升降機(jī)構(gòu),,自動(dòng)化控制,減輕勞動(dòng)強(qiáng)度,。

Simple rewinding and unwinding device: independent material roll lifting mechanism, automatic control, reducing labor intensity.

|

![XQ-LB210C-商標(biāo)機(jī)印刷機(jī)[避杠款打底色專用]](https://ux3qhp.cn/uploads/250402/1-250402134R11A.jpg)